Adaptive Reuse and Renovations

Existing Conditions for Adaptive Reuse and Renovations

3D scanning technology is the fastest and most accurate way to capture existing conditions.

Most as-builts are inaccurate and incomplete. Designing renovations based on such drawings means that errors will be “designed in.” They’ll be completely invisible until construction begins, often becoming very time consuming and expensive to resolve.

3D laser scanning lets you see precise as-built information before work starts.

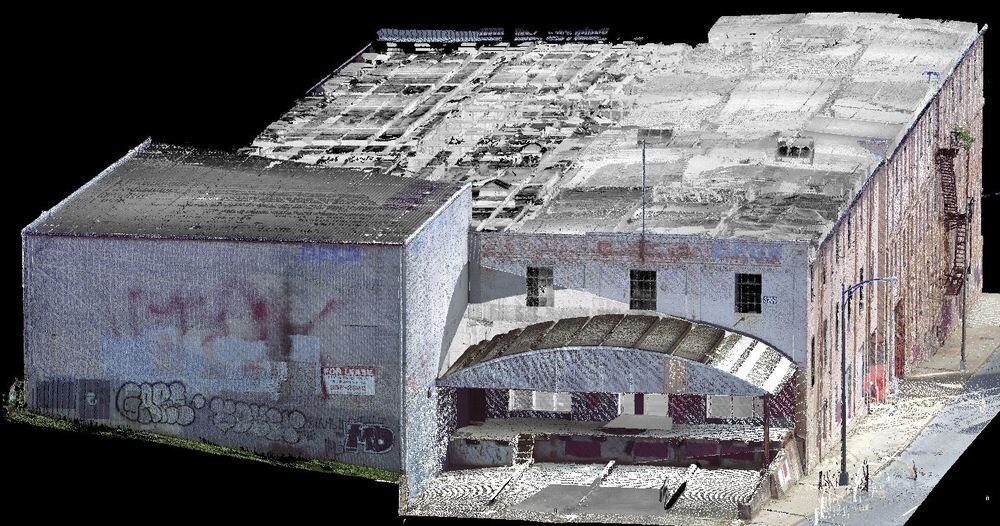

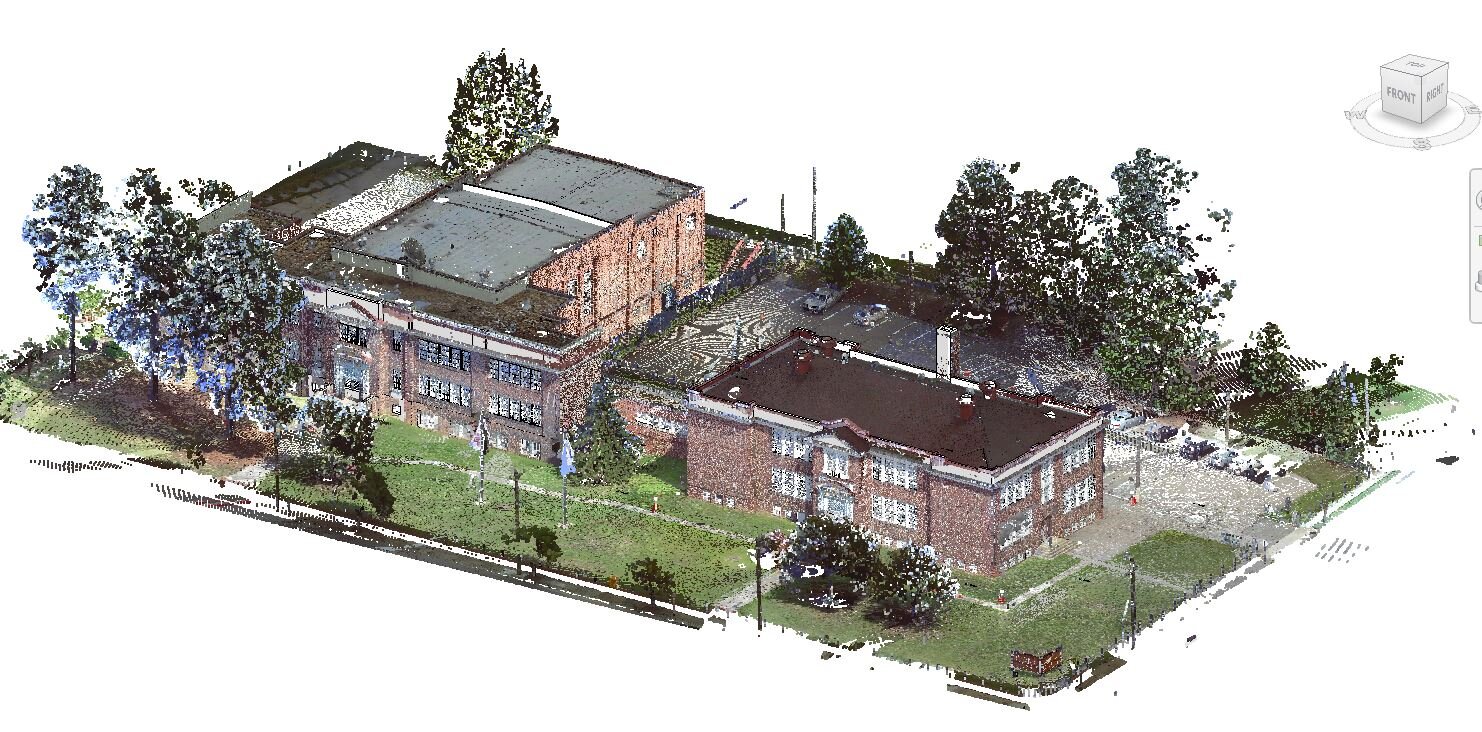

We use 3D scanning technology to collect point cloud data about all visible elements of a structure and produce existing conditions in a fraction of the time it would take with manual measurement.

3D scanning technology captures millions of data points per second, collecting accurate measurements to serve trustworthy starting point for adaptive reuse and renovation projects.

Benefits of Prologue 3D Scanning Technology:

Speed – Reduces onsite time by 50% to 70%. Working with digital data (versus manual measurements, notes and hand drawings) means that time spent on modeling is a fraction of the manual approach.

Accuracy – Accurate permanent records for both immediate and future use. It is real, trustworthy data delivered straight to your desktop, so you can build with confidence.

Safety – Measure objects from a distance, completely touch-free, in complex and hazardous environments. A safer and more versatile means of measurement than ever before.

Versatility – Virtually unlimited in size and environment, scans can be conducted in broad daylight, the dark of night, indoors, outdoors and across large distances.

Experience – We can provide anything from basic construction drawings to complex, ornate building information models. With over 80 years of industry experience, precision is our passion.

Deliverables – We deliver models in whatever format best suits your need including Autodesk® Revit®, CAD drawings, orthophotos, point clouds and more.

“Using the model allowed us to show the structural engineer the exact layout of the existing structure, adjacent mechanical equipment and required clearances. We were able to shift the unit in the model, minimizing redesign and reinstallation of roof supports – and additional costs for the customer.”

— Project Manager, ColonialWebb

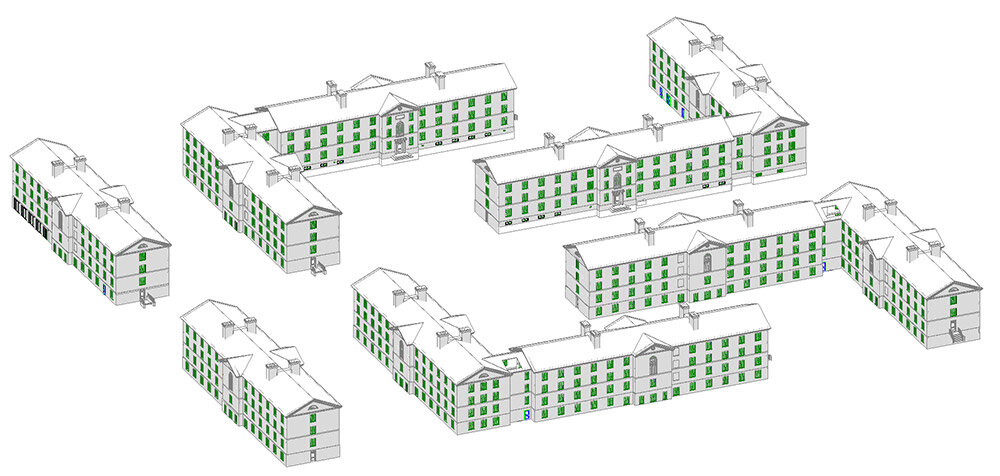

Existing Conditions with Scan-to-BIM

See details of visible building elements and view data in a 3D virtual environment right on your desktop.

Our BIM modeling experts create 3D replicas of buildings to reveal precise measurements and provide a real, trustworthy starting point for adaptive reuse and renovation projects.

With our NavVis indoor mobile mapping technology, each scan can be viewed in a 360-degree color photograph view with underlying measurement points collected by the scanner. This allows measurements to be pulled directly from the indoor photo views as well as the 3D models that are developed.

“Just to visualize the site in 3D helped us to make educated building decisions, not to mention saving us costly and time-intensive field work.”

— Bradford B. Sauer, Vice President, Sauer Properties Inc.

Get accurate information on pipes, HVAC, floors, structural steel and more to create a record of what is behind walls, under floor slabs and above ceilings that owners can utilize throughout the lifecycle of the building.

Verification & Analysis

In addition to producing accurate existing conditions, 3D scanning technology can continue to add value by capturing construction milestones and providing quality assurance as the project progresses.

Scan data is used to quickly evaluate work on a weekly or daily basis and assure that the work put in place is as designed. Individual scans are dropped into a BIM or CAD environment, making conflicts easy to identify and allowing exact measurements to be sent to the design team so revisions can be made and rework minimized.

We also quickly assess building elements like elevator shafts and concrete floor flatness, easily calculating what areas need adjustment and even determining the accurate volume of material needed.